TOKYO--(BUSINESS WIRE)--Mitsui Chemicals, Inc. (Tokyo: 4183; President & CEO: HASHIMOTO Osamu) today announced that its UNISTOLE™ polyolefin-based liquid adhesive has been adopted for use by Siemens Pte Ltd in Singapore as a coating agent on the 3D-printed frame of a new medical-grade face shield.

Looking to make prompt contributions in the fight against COVID-19, the Siemens Advance Manufacturing Transformation Center (AMTC) – a competence center that provides guidance, support and training to companies for their digital transformation journey –developed and manufactured a medical-grade face shield in just two months. This face shield was designed by Tan Tock Seng Hospital (TTSH) and TTSH has been trialing the optimized product since June.

Mitsui Chemicals has contributed to Siemens’ prompt development here by providing UNISTOLE™, offering up the polyolefin-based liquid adhesive for use as a coating agent for the frame component of these face shields. Produced using 3D printing equipment at AMTC, the frames contain micropores on their surfaces – an issue given that viruses and bacteria can reside within these pores.

But by coating the frames with Mitsui Chemicals’ UNISTOLE™ polyolefin-based liquid adhesive, it is possible to achieve (1) good adhesion with the frame material, (2) a flatter surface to prevent virus and bacteria residue, (3) resistance to alcohol that can be used for sterilization to facilitate face shield reuse, (4) scratch resistance, (5) improved elasticity, (6) crack resistance and (7) sterilization by way of low-dose UV resistance. As such, not only does the adhesive give the 3D-printed frame a smoother surface; it also provides added strength, flexibility and sterilization potential – greatly enhancing reusability of the product as a whole.

Going forward, Mitsui Chemicals will continue to help solve societal issues by offering its products for use in COVID-19 countermeasures.

What is UNISTOLE™?

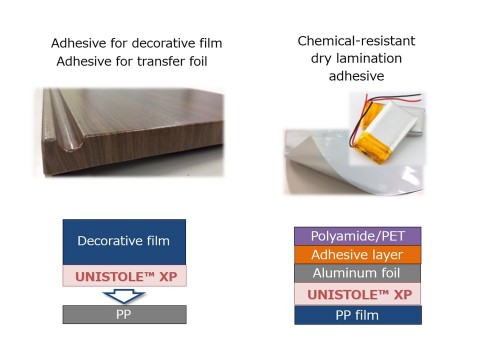

UNISTOLE™ is a liquid-form primer and adhesive based mainly on a modified polyolefin, which itself is created by using proprietary technology to introduce a polar group to the polyolefin. Previously, UNISTOLE™ has been used as a coating or adhesion primer, or as an adhesive itself, for a wide range of materials, including not only polyolefin plastics such as polyethylene (PE) and polypropylene (PP) – which have a reputation for making adhesion and bonding difficult – but also various engineering plastics.

The UNISTOLE™ XP series, which was adopted for this latest project under Siemens, also serves as a benzene, toluene and xylene (BTX)-free heat-sealing agent, as well as a chemical-resistant dry lamination adhesive.

-

For more information on UNISTOLE™, please see:

https://jp.mitsuichemicals.com/en/service/packaging/coatings/unistole/index.htm -

Press release from Siemens:

https://press.siemens.com/sg/en/pressrelease/siemens-fast-tracks-production-medical-grade-face-shields-covid-19-frontliners