“Polyester is the most widely utilized fiber on the planet, and it’s time for transformative change,” said Eddie Ingle, Chief Executive Officer of UNIFI, Inc. “Textile brands can now create solutions with the entire product life cycle in mind and work towards achieving their 2030 environmentally preferred materials targets. Our goal is to provide the best-in-class sustainable products that eliminate the need for virgin materials and reduce carbon emissions.”

Made from 100%* recycled polyester feedstock, with at least 50% textile waste, the two new products both achieve virgin-quality standards. The Textile Takeback™ process recycles both global post-industrial and post-consumer textile waste into next-generation materials using proprietary technologies. Further enhancing value throughout the supply chain, UNIFI will also partner with global brands to take back their waste and keep materials in circulation longer.

With widespread versatility across industries, applications, and colorways, the new circular REPREVE filament yarn is a white, dyeable, high-performance polyester that is designed for the most critical applications. The circular REPREVE polyester line, which also includes black filament yarn and black and white staple fiber, contains the inherent FiberPrint® tracer technology, meaning that all products can gain U-Trust® certification.

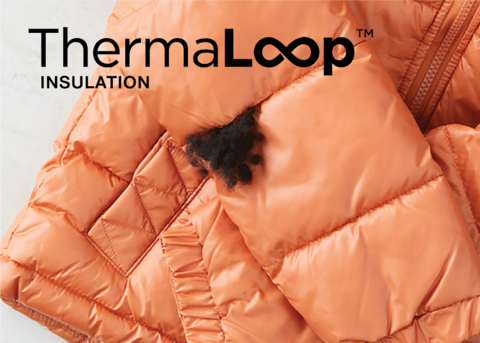

ThermaLoop™ insulation, available in down-like fiber, fiberball, and padding, offers performance, recovery, and thermal efficiency. The padding is engineered with REPREVE low melt fiber, a pioneering innovation that enables the production of 100%* recycled synthetic padding. Driven by UNIFI’s ‘waste nothing’ philosophy, ThermaLoop’s launch in black insulation showcases the wide variety of textile waste that can be utilized as feedstock.

The two new products are both available globally now, and can be integrated seamlessly into existing supply chains, without disruption. This commercial scalability tackles a key challenge for polyester-reliant industries, particularly fashion brands, which have long sought to create circular apparel to meet sustainability goals. These products underpin UNIFI’s goal to recycle 1.5 billion T-shirts’ worth of textile waste by fiscal year 2030.

About circular REPREVE filament yarn, powered by the Textile Takeback process

- White, virgin-quality filament yarn made with 100%* recycled materials and contains at least 50% textile waste.

- This filament yarn can be dyed using standard dye processes.

- Yarn can be enhanced with UNIFI performance technologies, including anti-odor, moisture, and stretch.

- It is the only polyester fiber that is traceable with FiberPrint® technology and certified by U-Trust®, as well as being Oeko-Tex®, GRS, and SCS certified for recycled content.

About ThermaLoop, powered by the Textile Takeback process

- ThermaLoop padding, down-like fiber, and fiberball are made with 100%* recycled polyester feedstock materials, including at least 50% textile waste (exclusive of REPREVE low melt polymer).

- ThermaLoop padding is engineered with REPREVE low melt fiber, a breakthrough technology, enabling synthetic padding to be made from 100%* recycled materials.

- Engineered to be fast-drying, lightweight, and machine washable, this insulation delivers performance, recovery, and thermal efficiency, on the foundation of REPREVE sustainability.

- Testing performed, with IDFL, for CLO (a measurement for thermal insulation), recovery, and fill power demonstrates parity with standard insulation of the same specification.

- ThermaLoop is the only insulation product that is traceable with FiberPrint technology and certified by U-Trust, as well as being Oeko-Tex®, GRS, and SCS certified for recycled content.

To learn more, please visit UNIFI at hall 4.1–E72 at Intertextile Shanghai Apparel Fabrics, being held August 27th – 29th at the National Exhibition and Convention Center. For more information on UNIFI’s Textile Takeback program, please visit www.textiletakeback.com and www.repreve.com.

*100% recycled materials refers to the base polymer utilized but does not include additives and/or colorants.

About UNIFI®

UNIFI, Inc. (NYSE: UFI) is a global leader in fiber science and sustainable synthetic textiles. Using proprietary recycling technology, UNIFI® is a pioneer in scaling the transformation of post-industrial and post-consumer waste into sustainable products. Through REPREVE®, the world’s leading brand of traceable, recycled fiber and resin, UNIFI is changing the way industries think about the materials they use – and reuse. A vertically-integrated manufacturer, the company has direct operations in the United States, Colombia, El Salvador, and Brazil, and sales offices all over the world. UNIFI envisions a future where circular and sustainable solutions are the only choice. For more information about UNIFI, visit www.unifi.com.

About REPREVE®

Made by UNIFI, Inc. (NYSE: UFI), REPREVE® is the global leader in recycled performance fibers and resins. Using proprietary recycling technology, REPREVE leverages multiple waste sources, including single-use plastic bottles, ocean-bound plastic, textile waste, and recycled yarn. REPREVE has transformed more than 40 billion plastic bottles into recycled fiber, powering globally scalable products for world-leading brands. Made traceable with FiberPrint® technology and certified by U-Trust®, REPREVE spans sports apparel, fashion, home, automotive, construction, transport, military, medical, and packaged goods. For more information about REPREVE, visit www.repreve.com.

REPREVE®, ThermaLoop™, and Textile Takeback™ are trademarks of UNIFI, Inc. in the US and other regions.