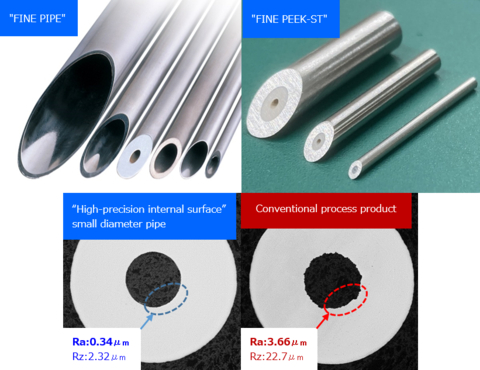

TOKYO--(BUSINESS WIRE)--NIPPON KINZOKU CO., LTD. (Headquarters: Minato-ku, Tokyo) has commercialized “FINE PIPE” *1, a welded drawn pipe that surpasses “seamless pipe” by using carefully selected materials and unique processing technologies (welding, drawing, annealing) only available from a raw material manufacturer.

These products meet the needs for higher precision in small-diameter pipe manufacturing, and we have received many inquiries and orders for the “FINE PIPE” series are expanding.

|

Features of "FINE PIPE" *1 |

|

| 1. |

Higher precision than seamless pipes, and continuous processing of coil products improves productivity and enables significant cost reductions |

| 2. |

Minimal thickness deviation, unique welding technology, and full length control of the welded part provide pressure resistance and durability that surpasses seamless pipes. |

| 3. |

Complete quality assurance system using in-line inspection equipment from materials to final products |

| 4. |

Selectable product supply options, such as coil-wound, fixed-length, cut-to-length, and specially processed products |

|

Notes: Refer to *1 for manufacturing range and steel grades handled. |

|

|

Features of “High-precision internal surface” small diameter pipe *2 |

|

| 1. |

Significantly improved inner surface roughness compared to conventional products |

| 2. |

The internal surface is perfectly round and well-formed, with stable quality in the longitudinal direction. |

| 3. |

No post-processing is required, resulting in significantly reduced costs compared to polished finishes. |

|

Notes: Refer to *2 for manufacturing range and steel grades handled. |

|

|

Features of "FINE PEEK-ST" *3 |

|

| 1. |

High-precision, high-strength column tube with PEEK resin pipe protected by stainless steel |

| 2. |

Can be used in ultra-high pressure environments of 100Mpa or more |

| 3. |

Dramatic improvement in roundness and internal surface roughness even with a small inner diameter (Internal surface roughness Ra 0.3 μm or less) |

| 4. |

The coil shape of up to 20M can be cut to any length, contributing to reduce costs and improve yields. |

|

Notes: Refer to *3 for manufacturing range and steel grades handled. |

|

*1 https://www.nipponkinzoku.co.jp/assets/images/2024/01/NIPPON-KINZOKUs-Welded-and-Drawn-Pipe-Fine-Pipe.pdf

*2 https://www.nipponkinzoku.co.jp/assets/images/2023/04/230418_nipponkinzoku_news_en.pdf

*3 https://www.nipponkinzoku.co.jp/assets/images/2024/03/d63791-36-7db4974674a5f0a2b8a581b4f6e4880e-Eng.pdf

About NIPPON KINZOKU Group

Our products have been used in a range of areas from the precision field to the construction industry. https://www.nipponkinzoku.co.jp/en/